About Maynard L. Dokken - Steps Wizard to Successful IP Future

A Different Approach | A New Market

The model holds true as UN Global Compact, Gartner, EY, Deloitte, ALM & HFS Research reveal, we had the future in our hands in 2009. The vision of an open source market solution optimizing automation, intelligence, resiliency & sustainability still applies.

Key players in the global supply chain management (“SCM”) market including SAP SE, Oracle, The Descartes Systems Group, Infor, IBM, Manhattan Associates, and Logility among others have dominance. We are very different yet as global or more.

A simple solution, supply chains that changed their reliance on centralized entities such as conglomerates. Centralized models that could easily cause stresses on commerce and ultimately the economy in the event operators were impaired by factors unrelated to their industry, vertical, product or service.

Even factors related to Supply Chain Operators (“SCO”) such as massive supplier shortages, backed-up transport networks, and miscalculated Environment, Social and Governance (“ESG”) factors or metrics can be mitigated.

The principle focus is two fold: to see if stresses could be overcome if the core resources needed to create value at each step or segment with an add value services framework could be delivered online; and build an Advanced Supply Chain Portal for Supply Chain Operators ("SCO") and User's Projects in a simplified user experience for transacting business.

The "Next Generation" step involved AI (Artificial Intelligence) & ML (Machine Learning) in a shared core framework to deliver information necessary for all stakeholders to forecast and manage core supplies and stresses in the supply chain before they cause downstream expenses.

The challenges were many including the need to control the launch in two pieces: confirm market acceptance of the model; then finish the Advanced Supply Chain Portal. During this process implement and enforce controls to protect and manage the idea or IP.

Conglomerates controlling resource monopolies and platforms such as Alibaba controlling most value add supply chains were the focus. The supply chain needs options including a more inclusive model. RIFIndustries has been working on solutions for these and other core issues to enable sustainable procurement visibility, decentralization, resiliency, and advanced technology adoption.

First a brief history on where we are and going next.

Intellectual Property

The starting point was the idea, a vision and architecture, the "Intellectual Property". We worked with top intellectual property firms and developed a protocol to manage and protect valuable IP . The development of this protocol happened through a firm called MarkCrest.

Step 1: Idea

The starting point is an idea, a vision, an architecture, the "Intellectual Property" that may be unique and could be valuable if protected. Click here...

To protect the idea in segments we first filed a patent for delivering and processing resources online. This allowed us to implement and confirm to the marketplace the model worked to incorporate into the backend platform a new solution for the global marketplace.

Step 2: Protect

Is the idea unique? If it is you need to decide how to create a framework to protect the idea. Click here...

The Stages

The Intellectual Property was developed in two stages. The first stage involved “Proof of Market” or the resources needed for the products in the supply chain.

Purchase Product

Our first step was purchasing the base product. The next step processing the material and delivering the value add product.

Add Value

This is a critical piece of any business. Adding value. In the first stage of the project was emulating the Alibaba model with a more automated structure to take the complexity out of the process. Much like aggregate vendors process material an online twist with options selected by the purchaser. Then sorting, breaking up and processing material into an add value product.

The second stage a value add services portal ASCP 1.0. The Advanced Supply Chain Portal or (“ASCP”) was an SharedMercantile ecosystem and the follow up patent drafted and ready for legal review.

Value Add Online Portal

Next Step was the development of an automated online value add portal to replace the Alibaba model. A more complete picture of the supply chain process and levels of stress with warning colors and reviews from verified sources.

The Interruption

During the course of this project the principal driver of the vision was Maynard L. Dokken. In October of 2009 he was hit by a drunk driver while getting into a cab after a meeting in Toronto. He had only been back in downtown for 45 minutes. He had a major appointment the next day for negotiating a partnership with one of the largest Trading Companies in the World. The focus was to take back the market from Alibaba with this new technology.

Legal & Recovery

The interruption provided an opportunity for individuals, entities, and statutory bodies entrusted with the responsibility to regulate capital markets and criminal activities to work together to support those individuals and entities that acted in a criminal manner and undermined the vision in many cases with malfeasance.

When Maynard L. Dokken had recovered from what was designated “catastrophic” injuries one of his first focuses was getting the product delivered to the customers. A lawsuit was filed in King County Superior Court and a multi million dollar judgment was awarded to the company.

At this point Maynard L. Dokken had run out of resources and had outstanding legal bills. Even though the judgment was served on a principal vendor that had failed to deliver they were unable to collect on the award. More funds were needed to track and serve the group of defendants and seek the monetary damages awarded.

He is currently working to rebuild this legal fund from his own work and collect on the judgment for the customers. He will then commence action for compensation on damages to the project.

The “Order of Relief”:

- Recover for the customers either their product or cash equivalent

- Recover the damages to Maynard L. Dokken and the Project which is minimally estimated in the 8 and 9 figure levels

- Complete the project and deliver a SharedMercantile solution to replace Alibaba

Finish What We Started

Ahead of the curve going towards automation, the digital supply chain twin, analytics everywhere, open source security mesh, ecosystem collaboration and sustainability. We can become the leaders again.

Once the second in “Order of Relief” or recovery of damages for Maynard L. Dokken has commenced either with Counsel retained and/or related actions started by RIFIndustries, the vision and work to replace the current outdated model will re-start. We are ready to complete the “Next Generation” supply chain model. As they say earlier is better!

Public: a public repository for public data and applications.

Private: a private repository for secure enterprise level access and management of Users by Supply Chain Operators ("SCO").

Open Source: application and server code for installation on most platforms including AWS Nitro.

New ASCP 2.0 Services & Libraries:

- Artificial Intelligence (“AI”) & Machine Learning (“ML”) Core

- Digital Core Supply Chain Twin for Real Time Backup and Disaster Recovery

- Analytics Public & Private Tools

- Open Source Security Mesh Core

- HyperAutomation

- Next Generation Robots & Integration

- Autonomous Process Optimization

- Sustainability Supply Chain Tools & Alerts

Collaborative Ecosystem Network for Supply Chain Tools & Alerts

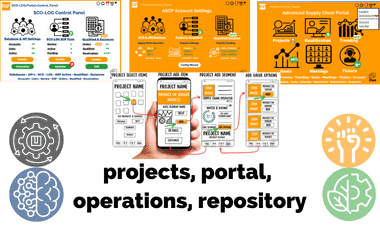

Projects: a simple 4 step process to add segments to a supply chain project

Portal: to manage User projects, qualifications, trending, goals, meetings and tickets

Operators: the “Accounts” section of the Advanced Supply Chain Portal (“ASCP”) to connect Supply Chain Operators (“SCO”) to Users

Repository: Four Components

- SCO/LOG Best Practices with SOP Integration

- Account Database API Connect with SDK

- Remote Database Creation

- Real Time Public Access to Supply Chain Status

HyperAutomation: a business-driven approach to rapidly identify, vet and automate business and IT processes through orchestrated use of multiple technologies including artificial intelligence (AI) and machine learning (ML). This ASCP 2.0 technology is to integrate AI & ML with other technologies and tools of the organization with the ASCP Core.

Next Generation Robots Integration: next-generation robots adaptive robots applied to a variety of tasks. Heterogeneous fleets of robots working together across different robots and different platforms. Robots that can interact with each other and communicate with other types of automated equipment like elevators and doors.

Security Mesh Core: a structured framework of governance, collaboration and applied technology orchestrated within the supply chains ensuring supply chain systems, tools, applications and people are safe and secure at all times. This includes the private and public network or ASCP Core integration to provide real time update of all security risks and threats.

Ecosystem Collaboration: tools to create a collaborative work environment to generate new and continuous shared value opportunities. A digital connectivity platform with key stakeholders.

A foundational network and tools to support continuous advancement in real-time across digital connections for people, data, machines, systems, processes and things.